Strong and reliable high-tensile wire quickly becomes a top choice for many applications. This type of wire stands out from the rest because of its remarkable strength, durability, and resistance to corrosion. Its special characteristics have made it an ideal option for a wide range of uses.

But what is high tensile wire, and what makes it stand out from other types of wires?

In this post, we’ll explore the composition, benefits, common uses of high-tensile wire, and the difference between high-tensile wire and mild steel wire.

[Buy High Tensile Galvanized Steel Wire]

Composition and Properties of High Tensile Wire

High tensile wire is a steel-based material that contains relatively low amounts of carbon, just like mild steel. But it also has several alloying elements, such as chromium, silicon, manganese, nickel, molybdenum, and vanadium.

These additional elements make the wire much stronger than regular mild steel and give it an excellent tensile strength of up to 100,000 pounds per square inch.

Through a robust heat treatment process and quenching technique which involves sudden cooling, the properties of high-tensile wire are permanently locked in for further durability and reliability. This makes it perfect for various purposes that require strong yet flexible materials.

Benefits of High Tensile Wire

High-tensile wire is an increasingly popular material for a variety of industries due to its numerous advantages. Some advantages include:

- Outstanding strength: This type of wire offers remarkable durability, making it suitable for tasks where part failure is not acceptable.

- Resistant to corrosion: The alloying elements within high tensile wire provide impressive corrosion protection, enabling the material to remain usable even in harsh or acidic conditions.

- Lightweight: Compared to lower tensile versions, high tensile wire is significantly lighter, which makes it ideal for transportation vehicles that need higher loads with decreased fuel consumption.

- Environmentally friendly: Producing high tensile wire results in fewer carbon emissions than steel made from iron ore, making it a more eco-friendly choice.

Common Uses of High Tensile Wire

High-tensile wire is often used in a variety of industries and applications due to its exceptional characteristics. These include:

- Springs, sprockets, and studs: High tensile wire has considerable strength, which makes it suitable for making springs, sprockets, and studs that can handle great force.

- Bridge construction: High tensile wire provides excellent reinforcement and support in massive projects such as bridges where sustainability is essential.

- Conveyor parts and gears: The impressive corrosion protection of high tensile wire makes it ideal for components in conveyors and gears, allowing them to work properly in harsh environments.

- Pinions and rotors: It is the perfect material to use when crafting pinions and rotors due to its tremendous strength and corrosion resistance.

- Axles and shafts: Its strength and reliability make it a great choice for creating axles and shafts that won’t fail under stress.

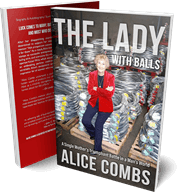

- Baling heavy large recyclables: Baling recycling, such as cardboard, polythene, film, paper, plastics, etc., allows you to sell your waste by the tonne for recycling, eliminate handling on site, and save money on disposal costs.

High Tensile Wire vs. Mild Steel Wire

Despite both high tensile wire and mild steel wire being types of carbon steel, there are particular distinctions between the two. These include:

- Strength: High tensile wire has a greater yield strength and tensile strength than mild steel wire, making it a more dependable material.

- Corrosion resistance: Thanks to its alloying elements, high-tensile wire tends to resist corrosion better than regular steel wire.

- Flexibility: Mild steel is more adaptable than high-tensile wire, which makes it ideal for uses that need greater malleability without compromising on sturdiness.

- Applications: Generally, mild steel is used for roof coverings, sheet piles, and other rolled sections, while high tensile wire is usually found in heavy-duty machines or equipment components where higher strength and resistance to deformation are necessary.

- Cost: High tensile wire usually costs more due to its higher quality but promises increased performance and durability that make it worth the additional expense.

Choosing the Right Wire for Your Project

Choosing the right wire material for a project requires considering several factors, such as strength, corrosion resistance, flexibility, and cost. High-tensile wire boasts impressive strength and protection against corrosion, making it ideal for applications requiring these properties.

On the other hand, mild steel wire is more flexible and malleable than its counterpart and may be better suited for projects that require this kind of flexibility. And there are also lots of other types of wire on the market, such as stainless steel wire, galvanized wire, and aluminum alloy wire.

No matter what type of wire you choose for your project, it’s important to weigh all the factors carefully before making a decision. That way, you can ensure you get the best possible results from your work.

Shop High-Quality Wire at Vulcan Wire

Here at Vulcan Wire, we understand the significance of using the right type of wire materials for your projects. That’s why we offer a wide selection of high-tensile wire and other top-notch products to provide you with the best solution for your needs.

[Buy High Tensile Galvanized Steel Wire]

Our experienced staff is always on hand to help you choose the perfect wire, guaranteeing your project succeeds. From our commitment to quality, customer service, and innovation, you can trust us to provide superior wire products that you’re looking for. Treat yourself to the extraordinary at Vulcan Wire – shop with us online today!